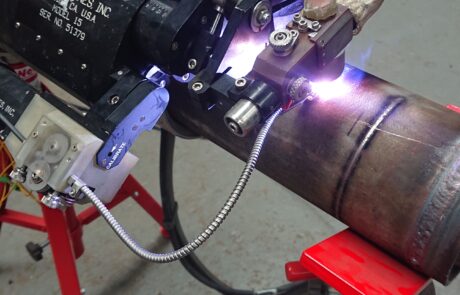

Orbital & Automated welding and cladding (TIG & MIG/MAG) of pipes, pipe systems & components insitu

Udccomb International tailorize and develop orbital welding (TIG/MAG) solutions for applications with the highest quality requirements. Uddcombs advanced orbital welding solutions are divided in 3 main categories:

- Uddcomb OPTIGAP = Tailormade orbital TIG welding solutions for components and pipes. Technology thats is developed with the main focus to limited stress and distortion in the HAZ.

- Uddcomb OPTICLAD = Tailormade internal diameter weld overlay & cladding solutions for nozzles and components insitu

- Uddcomb OPTICRO = Tailormade external diameter weld overlay & cladding solutions for components insitu

All our clients in this domain strive to eliminate welding failures since one single welding failure can have significant effect on both reliability on production equipment (pipes, tubes, nozzles, manifolds etc) as well as direct effects on potential loss of production if a welding failure occurs.

Depending on the application Uddcomb can use camera surveillanced and remote controlled orbital welding equipment.

In addition, Uddcomb develop and tailorize orbital welding repair concepts (including development of welding joints, filler material, equipment) together with our clients worldwide.

Orbital welding application of pipes, pipe systems and components is often used in the following industries with extensive demands on quality, reliability and performance:

- Nuclear

- Energy

- Oil & Gas

- Petrochemical

- Pharmaceuticals and medical industries

- Process

Applications with the highest requirements on reliability, safety & quality

Welding heads for a wide range of pipes, systems & components

Remote-controlled operations with camera surveillance is possible

Own development of orbital welding concepts (joints, filler material, methods)

ABOUT US

Uddcomb International AB are an advanced welding service contractor that provides lifetime extensions solutions, repairs and new builds of plant components onsite worldwide. By offering state-of-the-art refurbishments instead of replacements our solutions arent just cost-effective but also environmentally friendly. As an advanced welding service contractor we support our clients during their critical maintenance shutdowns & turnarounds globally.

Some examples of Uddcomb Internationals unique technologies, solutions and capabilities are:

- THE UDDCOMB METHOD® has provided superior corrosion/erosion protection of pressure vessels for more than 30 years

- Manufacturing of test blocks and test specimens for improved reliability of nuclear power primary components

- Manufacturing and installation of equipment for high voltage cable manufacturing

- Mechanized / Automated TIG & Orbital welding solutions onsite for highest possible quality requirements

- Advanced manual welding repairs and replacements of components

- Uddcomb OPTICLAD™ – Refurbishment, repair & corrosion protection of internal diameter small bore nozzles insitu

- Uddcomb OPTICRO™ – Corrosion Resistant Overlay welding of components

- Uddcomb OPTIGAP™ – Uddcomb Internationals advanced welding technology for orbital narrow gap welding with optimized metallurgical properties. Advanced orbital welding solutions that can be tailorized for multiple applications. A technology specially developed for the highest quality requirements.

GET IN CONTACT

Do you have a project that you that you would like to discuss? Fill out this form to get in touch.

Junior konstruktör med ambitioner

Junior konstruktör m [...]

Teknik & Konstruktionsledare

Teknik- och Konstruk [...]

Utrustningstekniker

Vi tror att vår kand [...]

Montageledare – Internationella projekt

Vi söker en driven m [...]

Team lead welders

Job description Udd [...]

OFFICE LINE

+46 735 35 68 91

sales@uddcomb.com

OFFICE LINE

+46 735 35 68 91