Mechanized & Automated Weld Overlay Solutions for corroded pressure vessels

Uddcomb International provides mechanized & automated weld overlay solutions for pressure vessels such as pulp digesters, crude distillation columns, reactors, vis-breakers/vacuum towers and boiler tubes worldwide.

THE UDDCOMB METHOD®

– The ultimate solution for corroded pressure vessels

Corrosion and erosion are major problems for the process industry. In recent years corrosion/erosion has increased after process modifications aimed at conserving energy, controlling pollution and increasing production. After years of operation, the corrosion margin is gone – and something must be done.

THE UDDCOMB METHOD® has been used extensively worldwide for restoring badly corroded and eroded pressure vessels for 30 years.

The results are excellent. Pressure vessels restored by THE UDDCOMB METHOD® show no sign of corrosion or loss of wall thickness.

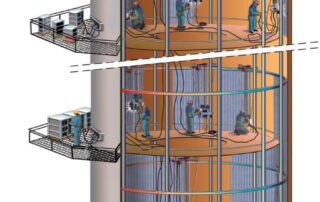

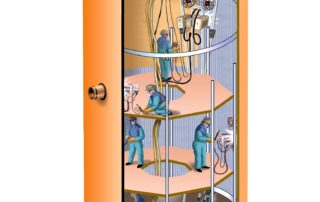

THE UDDCOMB METHOD® use a unique twin torch technology which can reduce the total welding time of the project by as much as 50%.

A layer of stainless material is overlay welded to the inner surface of the corroded pressure vessel. The welding is done on-site, using specially designed GMAW equipment.

The stainless steel weld overlay has metallurgical bond to the base metal, and has at least the same strength. The stainless layer gives excellent protection against further corrosion and erosion.

Quality is assured by careful base metal preparation and by qualification of the welding procedures. Welding equipment and execution of the work on site are carefully supervised by our experienced staff.

Compared with other renovation systems, overlay welding with THE UDDCOMB METHOD® proves a superior one.

With THE UDDCOMB METHOD® the stainless steel layer of metal becomes homogeneous, giving the pressure vessel added wall thickness and an excellent corrosion/erosion resistance.

Nobody, knows how long a renovated pressure vessel can last. The first projects were executed in 1987 and shows no sign of corrosion. We are convinced that pressure vessels renovated with THE UDDCOMB METHOD® will never need another major renovation again.

That is why we call it the ultimate solution.

Want to know more? Contact us!

THE UDDCOMB METHOD® – The ultimate solution for reliable life-time extension of corroded pressure vessels on-site

Since 1987 THE UDDCOMB METOD® have been the preffered solution for refurbishment and lifetime extension of corroded pressure vessels for many of the largest and most succesful companies in the process industry worldwide. We offer a proven solution with an excellent 30 year track record.

THE UDDCOMB METHOD® has +30 years of proven track record

Our clients are some of the most demanding and successful companies within their industries

With our unique twin torch weld overlay technology we can offer shorter outages

A unique weld overlay technology, originally based on experience from the demanding nuclear industry.

Our weld overlay method is designed for tailorization of new and challenging applications – Ask us and we will provide a solution for your industry needs

The Uddcomb technology makes it possible to solve corrosion and erosion problems in pressure vessels without having to repalce them = Huge cost savings as well as environmental benefits

ABOUT US

Uddcomb International AB are an advanced welding service contractor that provides lifetime extensions solutions, repairs and new builds of plant components onsite worldwide. By offering state-of-the-art refurbishments instead of replacements our solutions arent just cost-effective but also environmentally friendly. As an advanced welding service contractor we support our clients during their critical maintenance shutdowns & turnarounds globally.

Some examples of Uddcomb Internationals unique technologies, solutions and capabilities are:

- THE UDDCOMB METHOD® has provided superior corrosion/erosion protection of pressure vessels for more than 30 years

- Manufacturing of test blocks and test specimens for improved reliability of nuclear power primary components

- Manufacturing and installation of equipment for high voltage cable manufacturing

- Mechanized / Automated TIG & Orbital welding solutions onsite for highest possible quality requirements

- Advanced manual welding repairs and replacements of components

- Uddcomb OPTICLAD™ – Refurbishment, repair & corrosion protection of internal diameter small bore nozzles insitu

- Uddcomb OPTICRO™ – Corrosion Resistant Overlay welding of components

- Uddcomb OPTIGAP™ – Uddcomb Internationals advanced welding technology for orbital narrow gap welding with optimized metallurgical properties. Advanced orbital welding solutions that can be tailorized for multiple applications. A technology specially developed for the highest quality requirements.

GET IN CONTACT

Do you have a project that you that you would like to discuss? Fill out this form to get in touch.

Junior konstruktör med ambitioner

Junior konstruktör m [...]

Teknik & Konstruktionsledare

Teknik- och Konstruk [...]

Utrustningstekniker

Vi tror att vår kand [...]

Montageledare – Internationella projekt

Vi söker en driven m [...]

Team lead welders

Job description Udd [...]

OFFICE LINE

+46(0)73 535 68 91

sales@uddcomb.com

OFFICE LINE